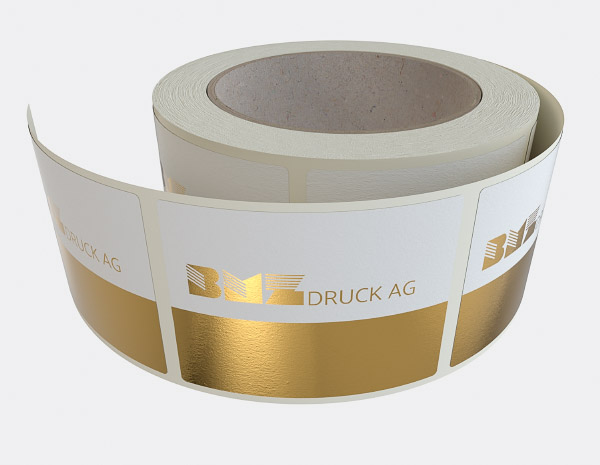

Embellished Labels

Our embellished labels elevate your product with high-quality finishes such as gloss varnish, embossing, or foil lamination. Ideal for brands that value a more striking appearance and wish to distinguish their goods on the shelf.

We offer the following embellishment options:

Other types of labels

Printed Labels

Our printed labels are produced using flexographic or digital printing techniques and are available in single-color, CMYK, and special colors. These techniques ensure clear, vivid designs that attractively display important information, draw customer attention, and guarantee unambiguous readability

Unprinted, Die-Cutted

Our blank labels are automatically die-cut and assembled in a variety of substrates, formats, and shapes. These labels are then printed during the customer’s packaging process using thermal transfer, direct thermal, inkjet, or other printing methods.

We tailor the assembly of the labels to your individual requirements and ensure they are optimally suited to your label printing systems.

Unprinted, Continuous

Unprinted, continuous labels (continuous rolls) are produced by us in a wide selection of label materials, formats, and shapes. Unlike die-cut labels, these continuous labels are not automatically die-cut but supplied as ongoing rolls. These labels can be printed during the customer’s packaging process using various printing methods such as thermal transfer, direct thermal, inkjet, or other techniques.

We tailor the assembly of the labels precisely to your specific requirements and ensure they are optimally suited to your label printing systems.