Mister Know-it-all

Understanding the Basics of Labels: Here, we break down the fundamentals of labels in a simple and understandable way. Whether you’re new to the world of labels or just looking to refresh your knowledge, you’ll find answers to your questions here. From different types of labels to basic terms and functions, let’s explore the world of labels together.

Mister Know-it-all

Understanding the Basics of Labels: Here, we break down the fundamentals of labels in a simple and understandable way. Whether you’re new to the world of labels or just looking to refresh your knowledge, you’ll find answers to your questions here. From different types of labels to basic terms and functions, let’s explore the world of labels together.

Mister Know-it-all

Understanding the Basics of Labels: Here, we break down the fundamentals of labels in a simple and understandable way. Whether you’re new to the world of labels or just looking to refresh your knowledge, you’ll find answers to your questions here. From different types of labels to basic terms and functions, let’s explore the world of labels together.

Adhesive Labels

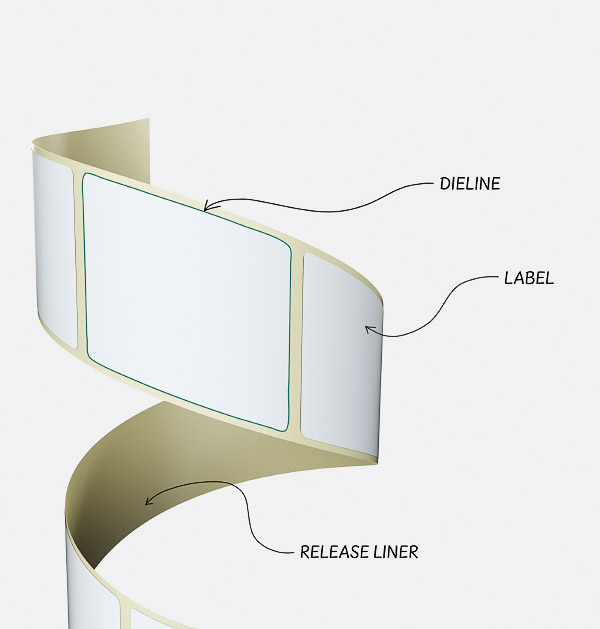

Adhesive labels, also known as Pressure Sensitive Labels (PSE) or Self-Adhesive Labels, are stickers or tags applied to various products. They include crucial information such as product names, manufacturer details, barcodes, and often instructions or warnings. These labels are used to identify, mark, and provide information about products for consumers.

Synonyms: Adhesive Labels, Pressure Sensitive Labels (PSE), Self-Adhesive Labels

Dieline

A die-cutting tool, also known as a die or die-cutting matrix, is a device used to cut materials such as paper, cardboard, or film into specific shapes. It consists of a metal frame with sharp blades or contours that separate the material as it is fed through the die. Die-cutting tools are commonly used in label production to cut labels into various shapes and sizes.

Synonyms: Die, Die-Cutting Tool, Cutting Die, Matrix, Die-Cutting Blade, Label Die

Release Liner

The release liner is the backing layer of an adhesive label that protects the adhesive until the label is applied. It ensures the label can be removed easily without unwanted sticking or detachment during handling and transport. Release liners are typically made from materials such as film or paper and are coated with a silicone layer to facilitate the easy removal of the label.

Synonyms: Liner, Backing Material, Release Liner, Carrier Sheet

Label Basic Parameters

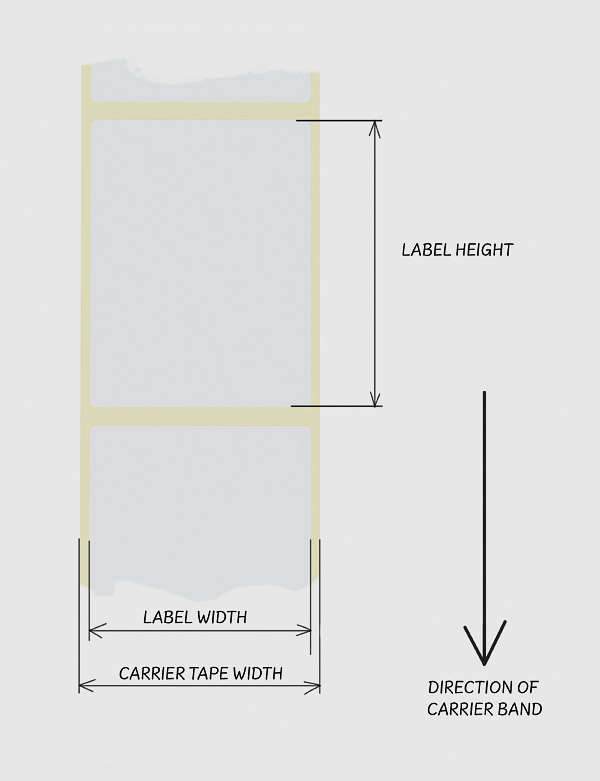

Carrier Tape Width

The carrier tape width refers to the width of the backing material on which labels are arranged. It defines the maximum width that the carrier tape can have to ensure smooth operation in labeling machines. An excessive carrier tape width can cause issues with feeding into the machine or affect the stability of the label roll during transport, while an insufficient width can negatively impact the stability of the labels on the carrier tape or the production process of label rolls.

Synonyms: Liner Width, Carrier Strip Width, Carrier Tape Width

Label Format

The format of a label is specified as Width x Height. The first number represents the width of the label (across the direction of the carrier band). The second number indicates the height of the label (along the direction of the carrier band).

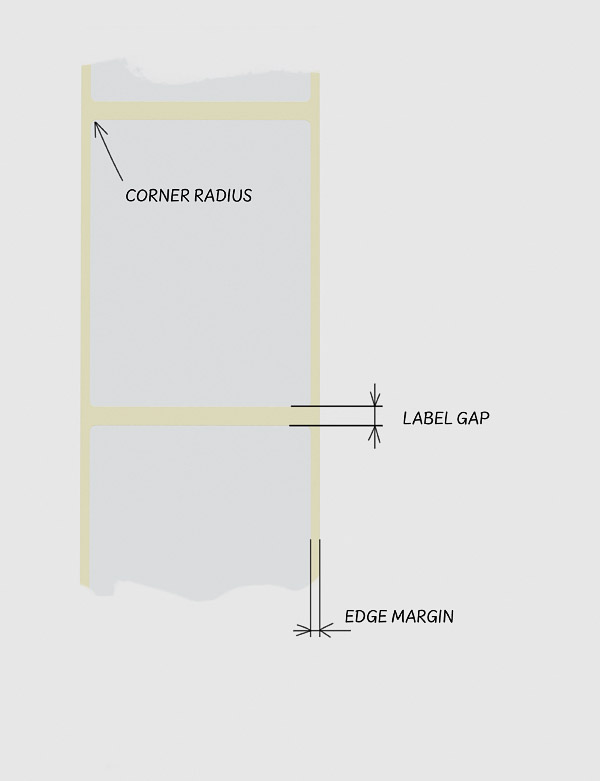

Edge Margin

The edge margin refers to the distance between the edge of the label and the edges of the label roll. It is crucial for accurate placement of the labels on the carrier material and for alignment in the labeling machine. Adequate edge margin ensures reliable processing of the labels and minimizes the risk of errors during the labeling process.

Synonyms: Margin Distance, Side Margin

Label Gap

The label gap, also known as the gap, is the distance between two consecutive labels on the carrier material. It allows labeling machines to accurately detect and separate the labels. The label gap can vary depending on the application and machine type and is crucial for a smooth labeling process.

Synonyms: Grid Gap, Gap

Corner Radius

The choice of corner radius depends on various factors, including the application, label design, and requirements for durability and aesthetics. A larger corner radius generally offers better durability and handling, while sharp corners can achieve a specific aesthetic design goal.

Standard corner radii we offer include:

– Rounded (Standard radius: 1.5 mm)

– Sharp (Radius: 0.5 mm)

– Custom radius as per customer specifications

However, other corner radii or custom die-cut shapes can be realized according to customer requirements.

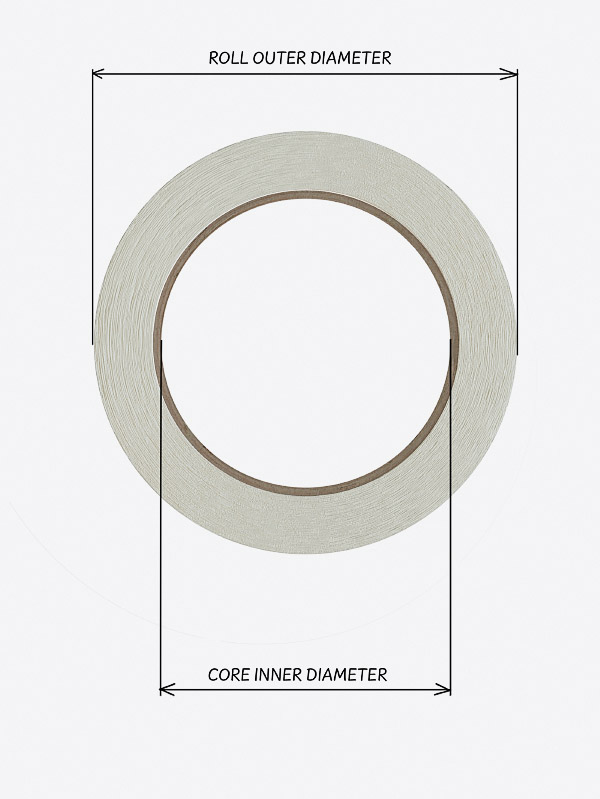

Roll Outer Diameter

This value is crucial for compatibility with labeling machines and the smooth operation of the labeling process. The roll outer diameter must not exceed the maximum roll diameter specified for your machine. A larger roll outer diameter generally allows for longer run times between label roll changes.

Synonyms: Roll Outer Diameter, Roll Outer Dimension, Roll Outer Measurement

Core Inner Diameter

This refers to the diameter of the inner core of a label roll. It is crucial for compatibility with labeling machines and allows the label roll to be mounted correctly on the machine’s feed system. A proper core inner diameter ensures that the label roll is accurately positioned on the machine and unwinds smoothly.

Synonyms: Core Diameter, Roll Core Diameter, Winding Core Diameter

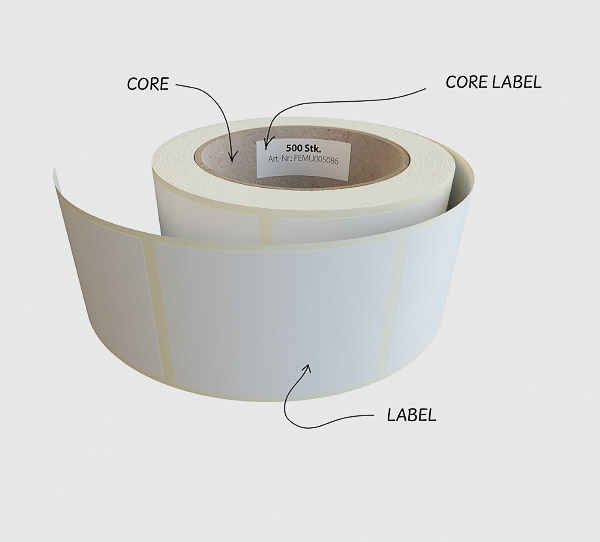

Core

The core, typically made from materials like cardboard or plastic, is the cylindrical structure at the center of a label roll onto which the labels are wound. It serves as the central axis, allowing the roll to be mounted on the labeling machine and facilitating smooth unwinding of the labels.

Synonyms: Winding Core, Roll Core

Core Label

Core labels are affixed directly to the core of a label roll. They typically contain important information such as the customer’s name, item number, or the number of labels on the roll. This type of label provides a convenient way to store relevant data and keep track of label rolls, even when they are partially used and the closure label is missing. Additionally, core labels aid in organizing and identifying labels during the labeling process, contributing to process safety.

Synonyms: Core Label, Sleeve Label

Closure Labels

Closure labels are specialized labels applied to the free end of a label roll to secure it and prevent uncontrolled unwinding. They serve to keep the roll securely closed and protect the labels during transport or storage. These labels are commonly used to secure and identify the roll after use.

Synonyms: Roll Closure Label, End Closure Label

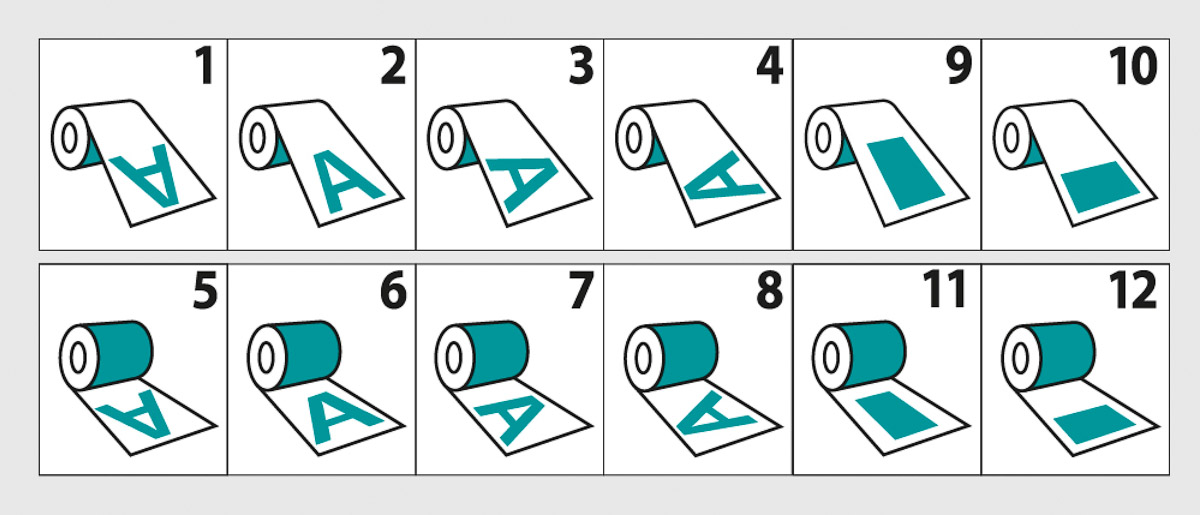

Rewind Pattern

The rewind pattern describes the arrangement and positioning of labels on a label roll. It specifies how the labels are arranged on the backing material and how they are unwound by the machine during the labeling process. This factor must be considered during the label production process to ensure efficient manufacturing. A precise rewind pattern is crucial for the correct placement of labels on the product and ensures a smooth labeling process.

Synonyms: Rewind Schema, Roll Pattern, Unwinding Pattern, Label Arrangement

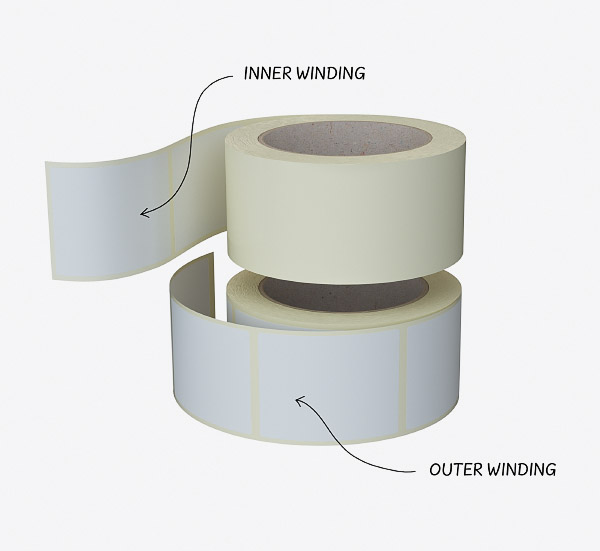

Winding

Winding refers to the manner in which the label material is wrapped around the core. Proper winding is essential for a smooth labeling process and helps prevent issues such as label jams or uneven unwinding. The winding hardness describes whether the material is wrapped tightly or loosely around the core.

Synonyms: Roll Winding, Label Winding

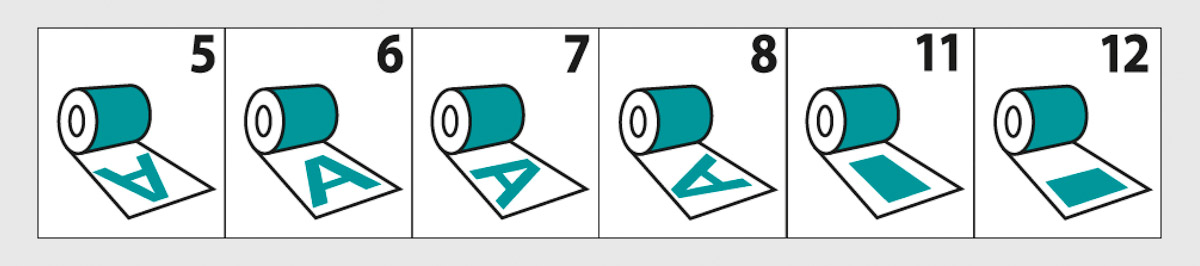

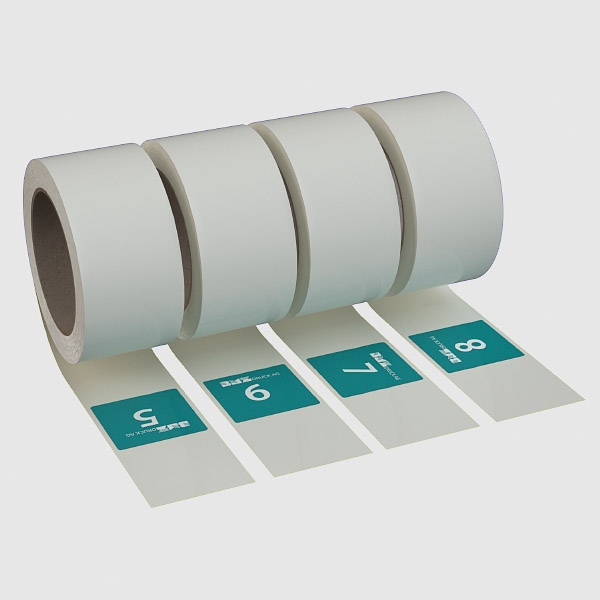

Inner Winding (Schema 5-8 and 11-12)

Inner Winding

(Schema 5-8 and 11-12)

In inner winding, the labels are positioned on the inside of the roll, and the liner is on the outside of the roll

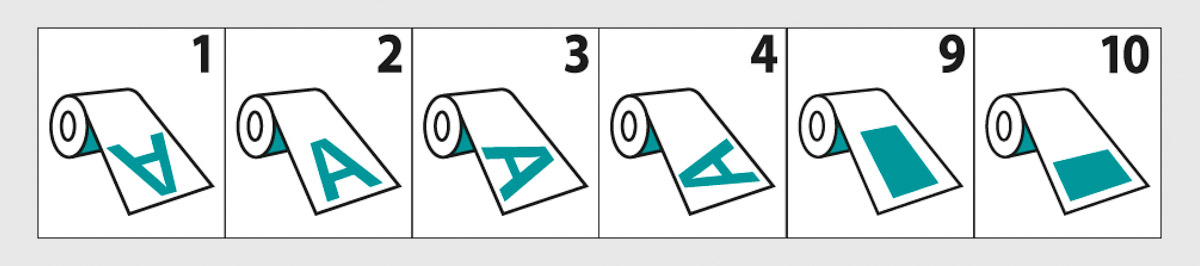

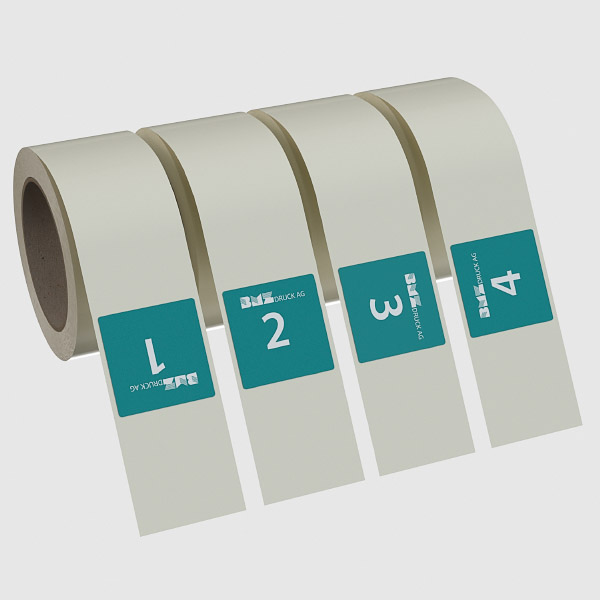

Outer Winding (Schema 1-4 and 9-10)

Outer Winding

(Schema 1-4 and 9-10)

In outer winding, the labels are positioned on the outside of the roll, and the liner is on the inside of the roll.

The individual unwind schemas differ not only based on inner or outer winding but also in how the label’s print image is positioned on the roll.

For unprinted labels, where there is no print image, the distinction is made based on how the label contour is oriented relative to the unwind direction. This results in six schemas for outer winding and another six schemas for inner winding.

Unwind schema Outer Winding

Schema 1–4 (printed)

Schema 9–10 (unprinted)

Unwind schema Inner Winding

Schema 5–8 (printed)

Schema 11–12 (unprinted)

Embodiments

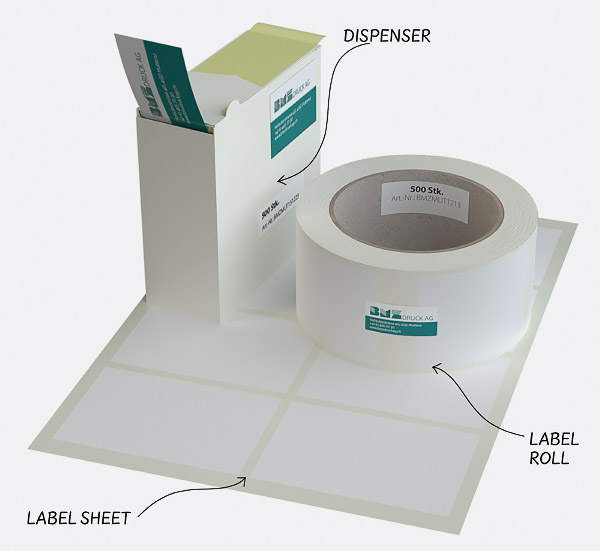

Label Roll

The label roll consists of a cylindrical core around which label material is wound. It is used in labeling machines and allows for a continuous supply of labels throughout the labeling process.

Label Sheet

Sheet labels are individual labels arranged on a carrier material such as paper or film. They are typically used in printers or label printing machines to print single labels.

Dispenser

A label dispenser in our case is a cardboard box designed for quickly and easily peeling labels from a small roll and applying them manually. It provides an efficient solution for the labeling process, especially for manual labeling of products.

Other technical terms

Thermal Transfer Labels

Thermal transfer labels are printed using a thermal transfer printer. In the printing process, heat is applied selectively via a print head to a thermal transfer ribbon, transferring the ribbon’s color film onto the label material at the specified locations. This creates the printed image on the label. Thermal transfer labels are used in various applications, including product labeling, shipping labels, barcode labels, and more. They offer a cost-effective and efficient way to encode labels on-site.

Direct Thermal Labels

Direct thermal labels are a type of label that is printed without the use of ribbons or inks. They consist of a substrate coated with a heat-sensitive layer that reacts to heat. During the printing process, the thermal printer applies heat directly to the thermal paper, darkening the heated areas and making the desired information visible on the label. Since no ribbon is required, this printing method is simple and cost-effective; however, the print is not very durable. Direct thermal labels are particularly suitable for applications where short-term labeling is needed, such as shipping labels, inventory labels, tickets, and receipts. They provide a clear and quick printing solution for various applications.