Pharma

Our label solutions for the pharmaceutical sector meet stringent safety standards, including quality processes according to ISO 15378, to ensure the quality and safety of your pharmaceutical products. Our labels support the precise and secure labelling of medications and other pharmaceutical products to comply with regulatory requirements and guarantee patient safety. Our goal is to protect the integrity of your products through reliable, accurate, and fully traceable labels.

Pharma

Our label solutions for the pharmaceutical sector meet stringent safety standards, including quality processes according to ISO 15378, to ensure the quality and safety of your pharmaceutical products. Our labels support the precise and secure labelling of medications and other pharmaceutical products to comply with regulatory requirements and guarantee patient safety. Our goal is to protect the integrity of your products through reliable, accurate, and fully traceable labels.

Pharma

Our label solutions for the pharmaceutical sector meet stringent safety standards, including quality processes according to ISO 15378, to ensure the quality and safety of your pharmaceutical products. Our labels support the precise and secure labelling of medications and other pharmaceutical products to comply with regulatory requirements and guarantee patient safety. Our goal is to protect the integrity of your products through reliable, accurate, and fully traceable labels.

Tamper Evident Labels

This label design is specifically developed to ensure the security of pharmaceutical products by making it visibly clear if a package has been tampered with.

Flag-Labels

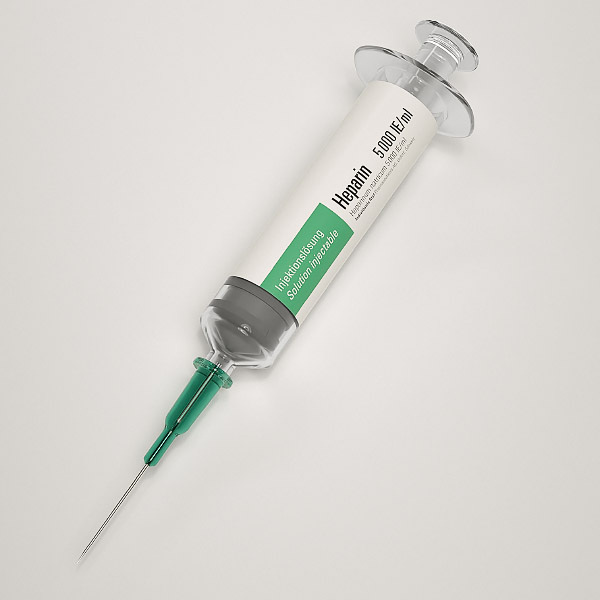

These specially designed labels are ideal for clear and space-efficient labeling of syringes and other cylindrical containers in the pharmaceutical industry.

Syringe Labels

These labels are specifically designed for precise and clear labeling of syringes, ensuring accurate information even on the smallest diameters.

Multipager Labels

These labels offer extended informational space through their multi-page design, making them ideal for pharmaceutical products that require extensive information such as dosage instructions and legal notices.

Printed Labels

Printed pharmaceutical labels are produced using flexographic or digital printing techniques and are available in options ranging from single-color to CMYK and special colors. These techniques ensure clear designs, guaranteeing the unambiguous readability of important information.